Getting The Steel Road Plates To Work

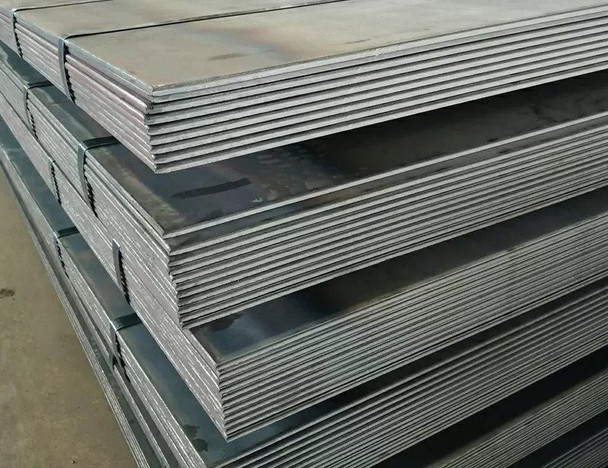

Steel layers are offer an excellent, short-term solution for covering harmful holes on a building website. These heavy-duty, robust plates allow roadways to return to solution to ensure that building can continue. Below we explore the style information and best method installation guidance. These plates can be utilized to ensure that roadways can still be utilized whilst other stages of work continue.

They are commonly seen when excavations have begun as a very early stage of building or repair projects. These plates are created to withstand heavy-duty usage on active roads.

The weights begin from roughly 300kg and typical road plates have a density of either inch or inch. The capacity to be bolted to the road.

Not known Details About Steel Road Plates

Hinged variations for quick accessibility to the excavation or regular gain access to, e.g. driveways. Composite plates, which can suit different lengths of trench. Skid-resistance for enhanced vehicle, pedestrian and website employee safety and security. Steel road layers can be set up fairly quickly, yet they are hefty. Therefore, they must be set up utilizing a forklift or crane.

Look for displacement by traffic filling from the outset plates must always resist variation. Inspect that home plates do not provide a danger to any kind of road customer and can be made use of by all road customers and automobile types, including pedestrians, cyclists and motorcyclists. Create a regular inspection and upkeep to make certain that efficiency remains secure and maximum.

Repair the plates properly at all times. Mechanical lifting guarantees that the plates are set up properly and securely.

If a ramp is developed by the roadway layers, then advising indicators for pedestrian and road individuals are needed. Always a conduct complete site survey, and take the expert guidance of a structural designer.

The Single Strategy To Use For Steel Road Plates

In order to improve safety and security, there are a number of standards and industry files guiding their usage in building job areas. Steel plates need to be repaired in area to avoid motion.

The Main Principles Of Steel Road Plates

In enhancement to being securely in contact with the pavement, they must be either her comment is here pinned, recessed into the sidewalk, or safeguarded with asphalt wedges around the border. Pinning right into the sidewalk involves driving pins into the sidewalks along the sides of the steel plates to avoid movement. Recessing includes eliminating the location where the steel plate will be placed.

This leads to the steel plate being flush with the sidewalk. Additionally, when several steel plates are used and butt as much as each various other, they should be bonded with each other at the longitudinal seams. Steel plates can be really slippery, particularly when they are wet, unless they have an anti-skid layer used.

Treatment steel layers with a material that increases friction helps motorcyclists and bicyclists retain control, especially in wet climate. Conditions which minimize pavement rubbing in work areas are of specific issue to motorcyclists and bikes. An usual threat in steel plate installations happens when the individual stops working to construct properly tapered ramps from the road to the edges of the steel plate( s).

The Buzz on Steel Road Plates

It poses a considerable risk to motorcyclists and bicyclists that can easily lose control when they speak to the abrupt/steep tapered ramp and the steel plate. Effectively tapered ramps allow users to safely go across over the steel plates.

Division of Transport's Federal Highway Management important link (FHWA) needs that transverse sidewalk joints, which lead to a bump, need to be tapered at 60 to 1 (5 feet straight for each 1 inch of upright elevation difference). Select the appropriate dimension. Guarantee ample overlap. Usually, steel plates must extend at the very least one foot past the sidewalk opening onto company ground.

Steel Road Plates Fundamentals Explained

Welding is used when more than one steel plate is used and they butt up to each various other. Plates must be countersunk when required due to uneven highways.

His history includes the building, evaluation, find out more.

These sturdy steel plates play a critical function in enhancing building and construction security, supplying short-lived streets, and making sure smooth procedures on various job sites. As a building tools distributor, their significance can not be overemphasized.